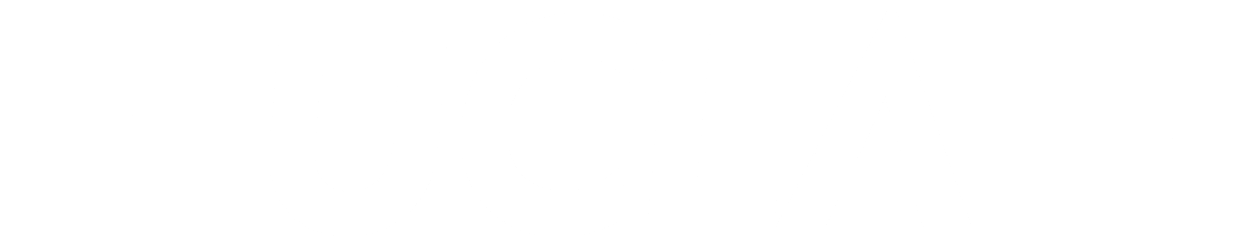

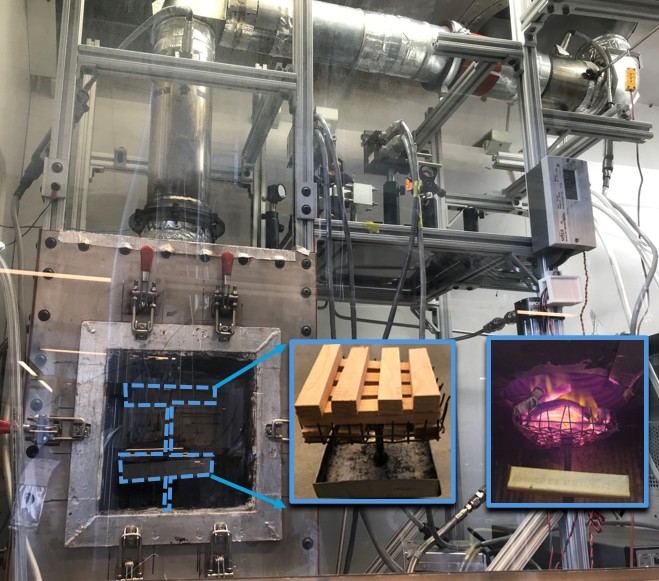

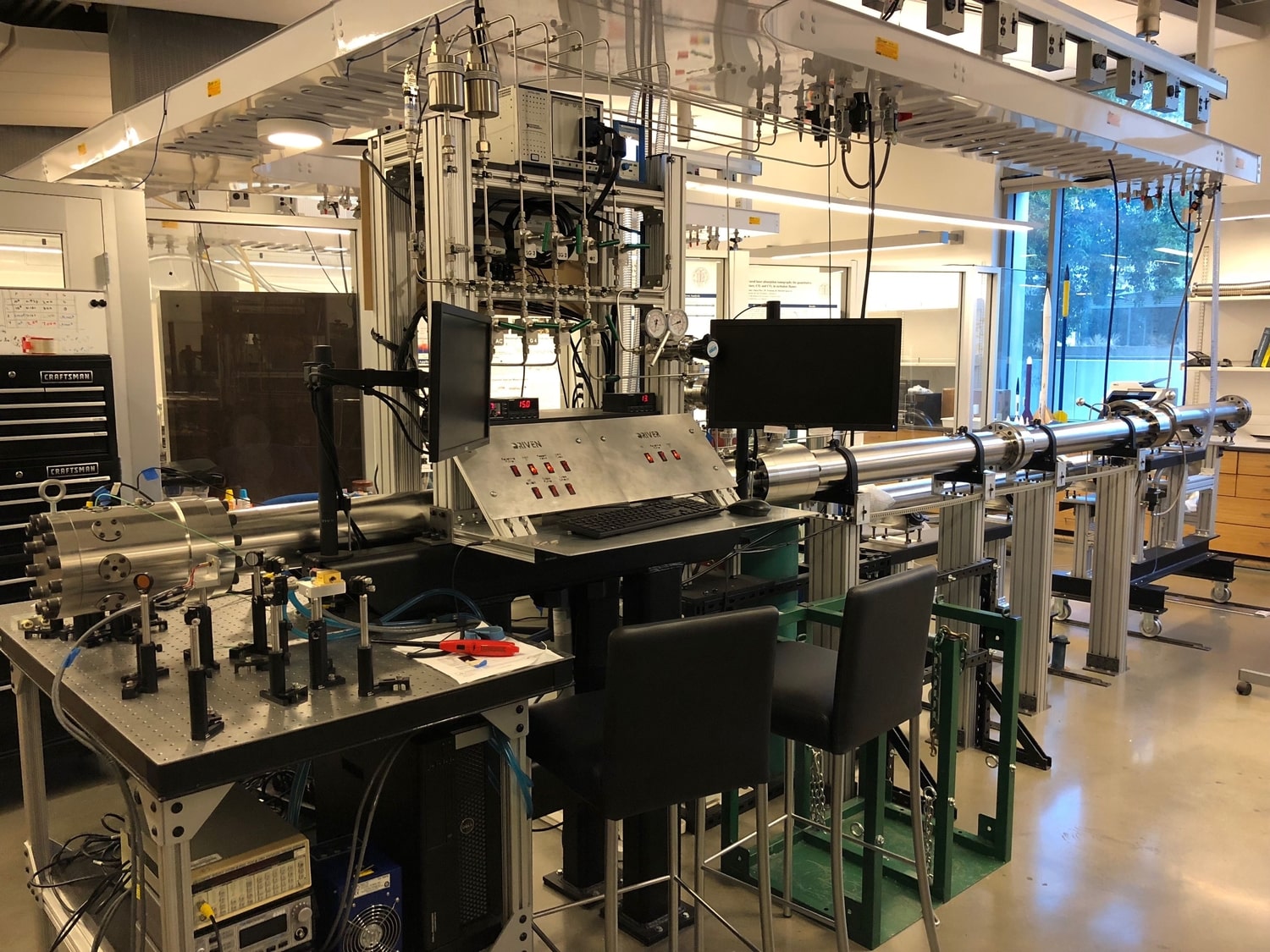

High-Enthalpy Shock Tube (HEST) Facility

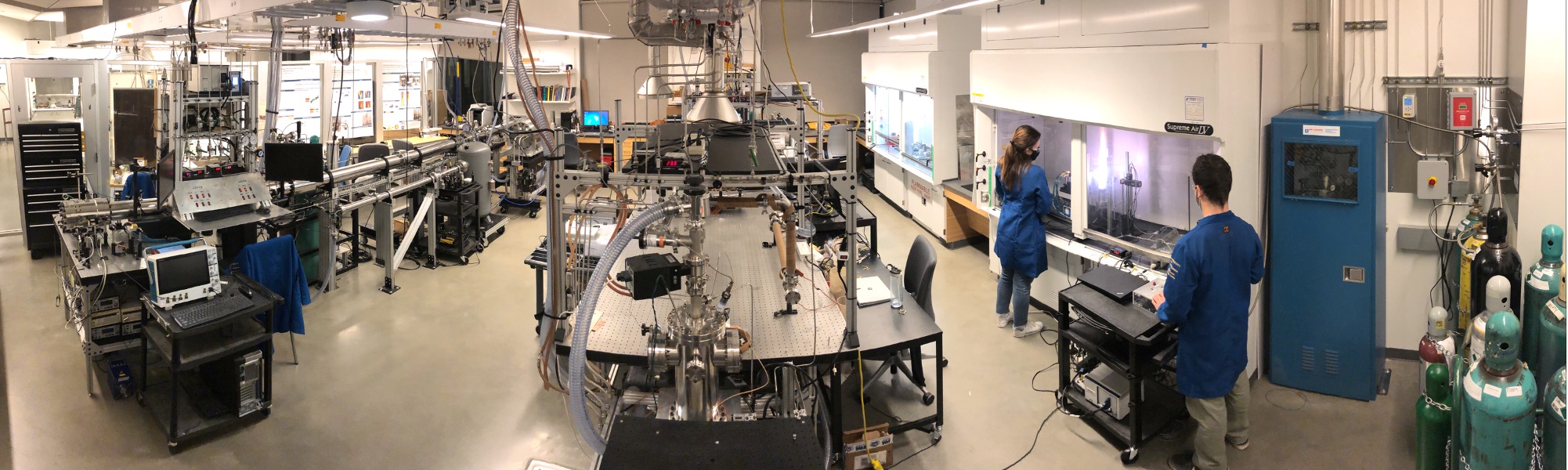

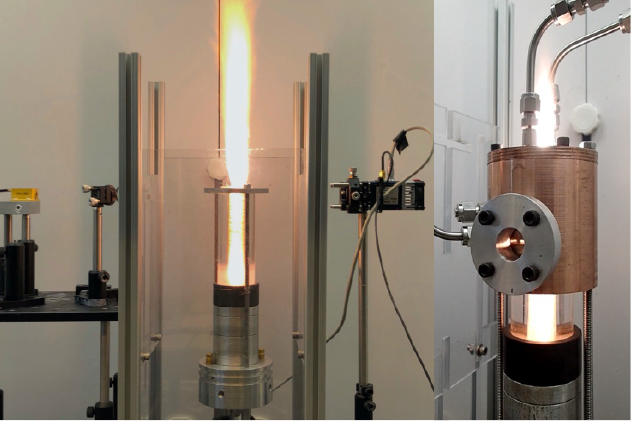

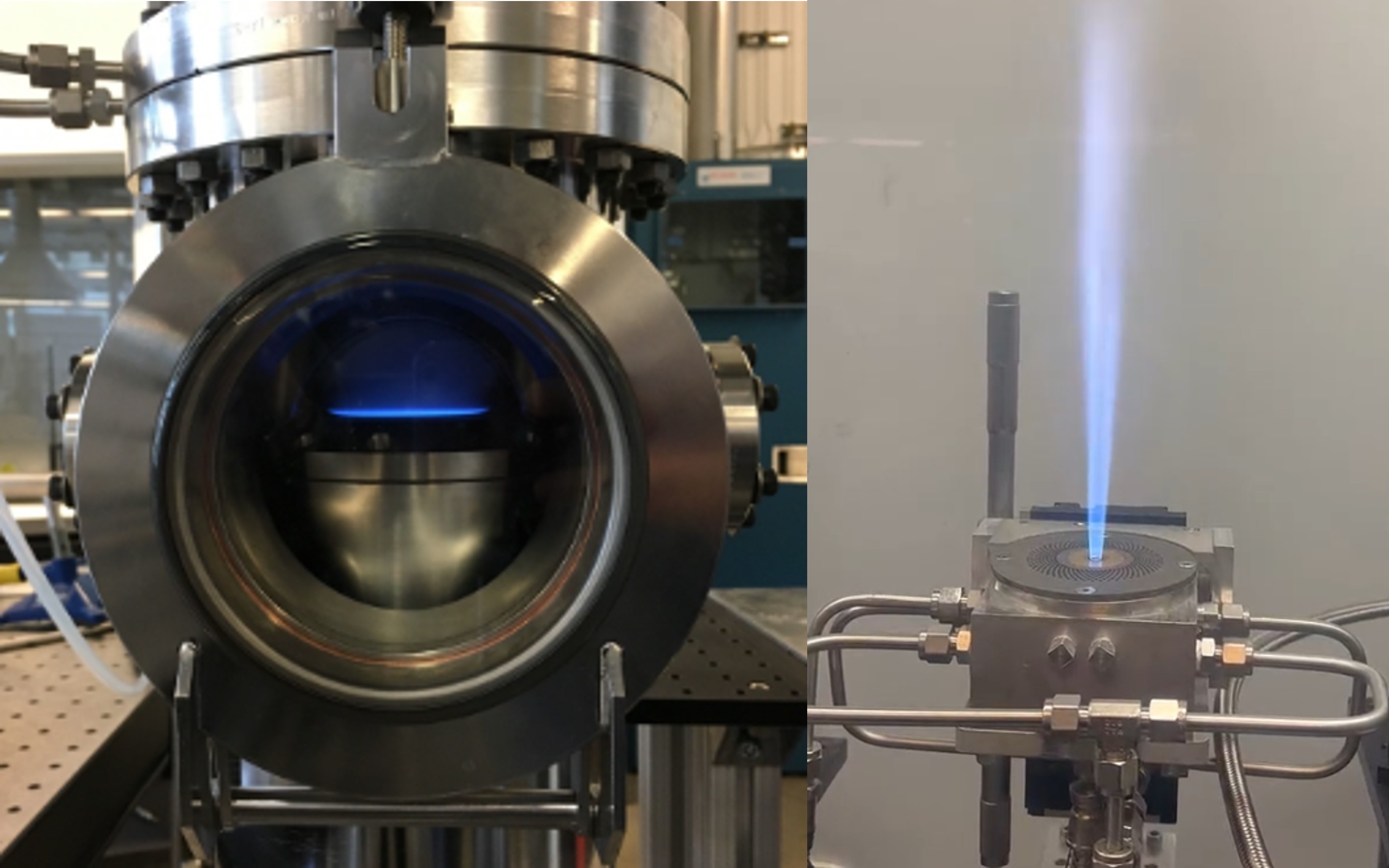

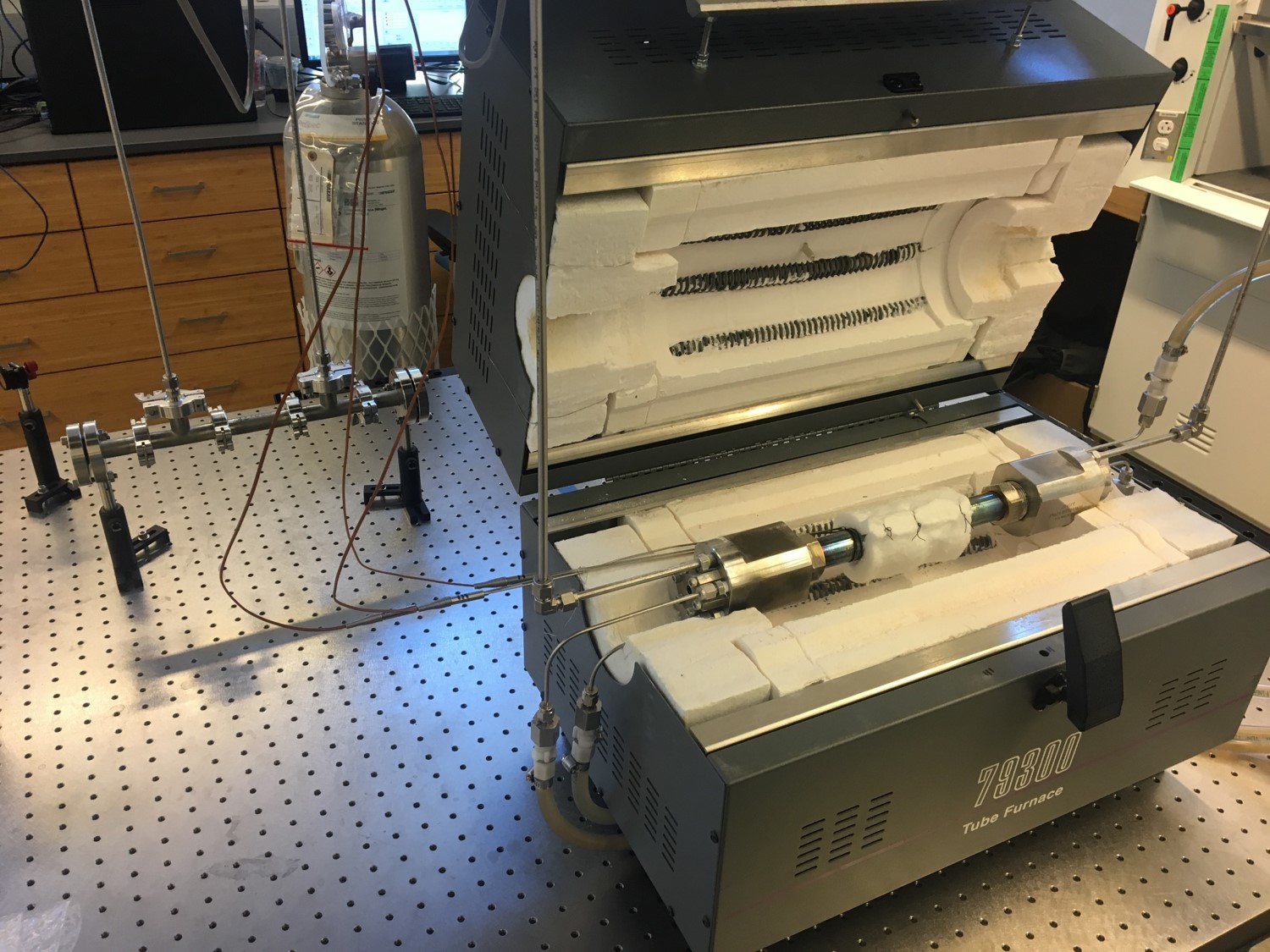

The HEST facility utilizes the principle of unsteady shock heating and compression to generate precisely-known high-temperature and high-pressure test conditions to further the basic understanding of gas dynamics, radiative heat transfer, and chemistry at high enthalpies. An optically-accessible test section allows for the integration of laser diagnostics to measure time-resolved profiles of species and temperature.

Key Elements:

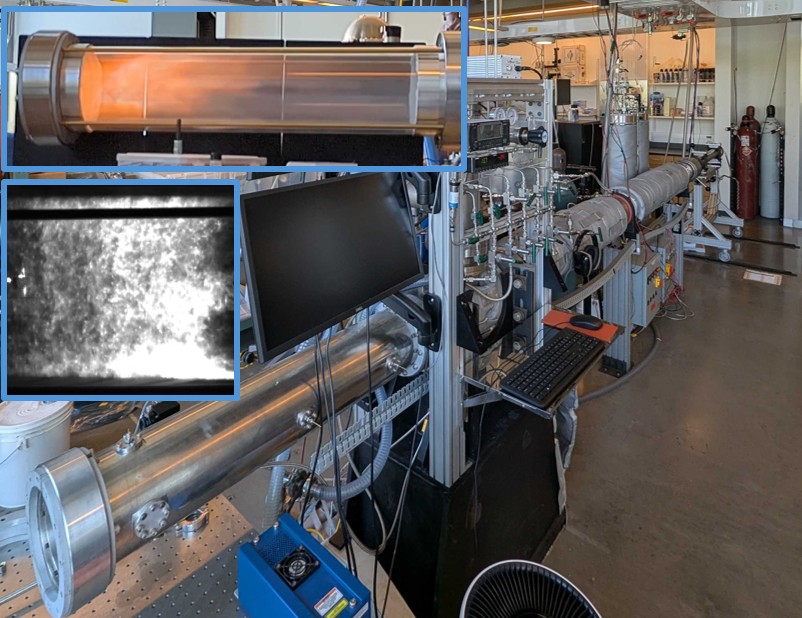

-10 cm inner diameter, electropolished stainless steel

-Modular design with driver extension to maximize test times (up to 30 ms)

-Custom low-profile double groove-locking weldless flanges

-Hydrostatically pressure tested to 265 atm

-Post-reflected shock temperature range of 600-12,000 K

-Quick diaphragm loading mechanism

-Optical access ~2 cm from endwall